Steel Frame Systems vs. Traditional Construction Methods

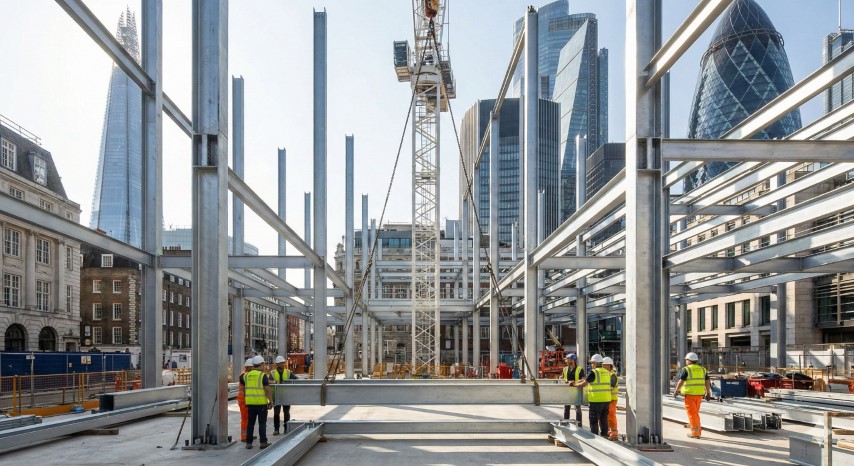

When planning a construction project—whether it’s a residential home, commercial unit, or large-scale development—the choice of structural system plays a critical role in the outcome. Historically, traditional construction methods using concrete and blockwork have been the go-to. But today, steel frame systems are rapidly gaining ground as the smarter, more efficient alternative.

So how do the two compare? Let’s break it down:

1. Speed of Construction

Steel Frame System:

Off-site manufacturing and on-site assembly drastically reduce build times. Steel components are prefabricated, delivered in sequence, and bolted into place quickly. There’s no waiting for curing or drying like with concrete.

Traditional Construction:

Largely manual and time-consuming. Bricklaying and concrete work are dependent on weather and drying time, leading to delays and longer project timelines.

Winner: Steel frame – faster delivery, reduced project time.

2. Design Flexibility

Steel Frame System:

Ideal for open-plan spaces and architectural freedom. Easily accommodates last-minute design changes during construction—new openings, layout shifts, or even structural changes can be done without major disruption.

Traditional Construction:

Less forgiving to change. Any structural alteration (like moving a wall or widening an opening) usually requires demolition, engineering rework, and extra time and cost.

Winner: Steel frame – flexible and adaptable to evolving client needs.

3. Cost Efficiency

Steel Frame System:

Although the initial material cost may be higher, the speed of build, reduced labor, minimal waste, and fewer delays result in overall cost savings—especially on larger or more complex projects.

Traditional Construction:

Lower material cost upfront, but higher long-term expenses due to labor-intensive work, waste, rework from design changes, and extended project durations.

Winner: Steel frame – lower lifecycle cost and better value in the long run.

4. Structural Strength and Durability

Steel Frame System:

Highly durable, non-combustible, and resistant to warping, rot, termites, or mold. With proper treatment, it withstands harsh conditions and offers long-lasting strength.

Traditional Construction:

Solid and time-tested, but vulnerable to weathering, cracking, moisture penetration, and pests over time.

Winner: Steel frame – superior durability with less maintenance.

5. Sustainability

Steel Frame System:

Made with recycled materials and 100% recyclable at end-of-life. Off-site fabrication also means less site waste and reduced environmental impact.

Traditional Construction:

Often waste-intensive with limited recycling potential. Concrete production has a high carbon footprint.

Winner: Steel frame – greener, cleaner construction.

6. Build Accuracy and Quality Control

Steel Frame System:

Precision-engineered in factory conditions using CAD design. On-site assembly is accurate and reliable, reducing errors and manual rework.

Traditional Construction:

Dependent on on-site workmanship, which can lead to inconsistencies and more frequent quality checks.

Winner: Steel frame – consistently high-quality results.

Final Verdict: The Smarter Way to Build

While traditional methods still have their place in certain projects, the steel frame system clearly outperforms across the most critical areas of construction—speed, flexibility, durability, and efficiency.

For clients, developers, and architects who demand high performance, adaptable design, and long-term value, steel frame systems offer a future-proof solution.

Thinking beyond bricks and mortar?

Talk to us about how a steel frame structure can deliver more—faster, smarter, and stronger.