Maximising Space and Efficiency: How Steel Frame Construction Unlocks Open-Plan Living and Superior Thermal Performance

While traditional masonry has its place, it often struggles to meet the dual requirements of expansive, open-plan design and rigorous thermal efficiency without incurring high costs or delays. This is where Light Gauge Steel (LGS) framing is transforming the market.

The Architecture of Light: Achieving Open-Plan Layouts

One of the primary drivers for choosing a steel framing system (SFS) over brick and block is the superior strength-to-weight ratio of steel.

In traditional construction, creating large open spaces often requires heavy, intrusive structural supports or thick load-bearing walls that eat into valuable floor space. Steel frame construction changes this dynamic. Because cold-rolled steel sections are incredibly strong yet lightweight, they allow for much larger spans without the need for intermediate columns.

For architects and homeowners, this means:

-

Design Flexibility: The ability to create the coveted “kitchen-living-dining” open-plan layouts without compromise.

-

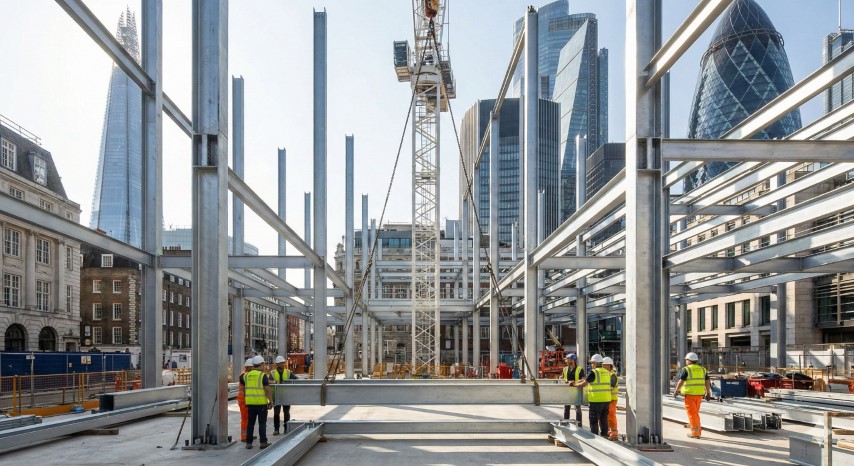

Urban Potential: The lightweight nature of LGS makes it the ideal material for rooftop extensions. Adding a storey to an existing London property is far safer and structurally viable when using steel compared to heavy masonry.

-

Thinner Walls, More Space: Steel frames can achieve the same structural integrity as blockwork within a much thinner wall profile, maximizing the internal Net Lettable Area (NLA).

Precision Engineering Meets Thermal Performance

With energy bills rising and UK Building Regulations (specifically Part L) becoming stricter regarding the conservation of fuel and power, the thermal performance of a new build is critical.

Off-site manufacturing ensures that every component of the BAS Frames system is produced to exact millimetre tolerances. Unlike a traditional building site, where weather and human error can lead to gaps and cold spots, factory-produced steel frames offer precision engineering.

This precision allows for:

-

Superior Insulation: Insulation can be fitted tightly within the frame profile itself, rather than just added on top, reducing wall thickness while maintaining low U-values.

-

Airtightness: The exact fit of components significantly reduces air leakage, a common issue in traditional builds that leads to heat loss.

-

Eliminating Thermal Bridging: Modern LGS designs utilise thermal breaks and specific cladding systems to ensure heat is not conducted out of the building through the frame.

Speed and The “Rapid Dry Envelope”

Perhaps the most practical benefit of Modern Methods of Construction (MMC) in the UK climate is certainty. Traditional builds are often at the mercy of the weather—bricklayers cannot work in torrential rain or freezing conditions.

Steel fabrication happens off-site, in a controlled factory environment, often while the groundworks and foundations are being prepared on-site. Once delivered, the frame is assembled rapidly. This allows the project to achieve a “rapid dry envelope”—the point where the building is watertight—weeks or even months faster than traditional methods.

For developers, this predictable programme means a faster return on investment. For homeowners, it means less time living in a construction site.

The Future is Framed in Steel

Whether it is a complex commercial infill project or a bespoke residential extension, the shift towards steel is undeniable. By combining the speed of prefabrication with the design flexibility of high-strength steel, BAS Frames delivers structures that are not only built for today’s aesthetic trends but are engineered for tomorrow’s environmental standards.

Are you planning a project that requires precision, speed, and structural innovation? Contact BAS Frames today to discuss how our Light Gauge Steel solutions can bring your vision to life.