Why Steel Frame Systems are Reshaping Modern Construction

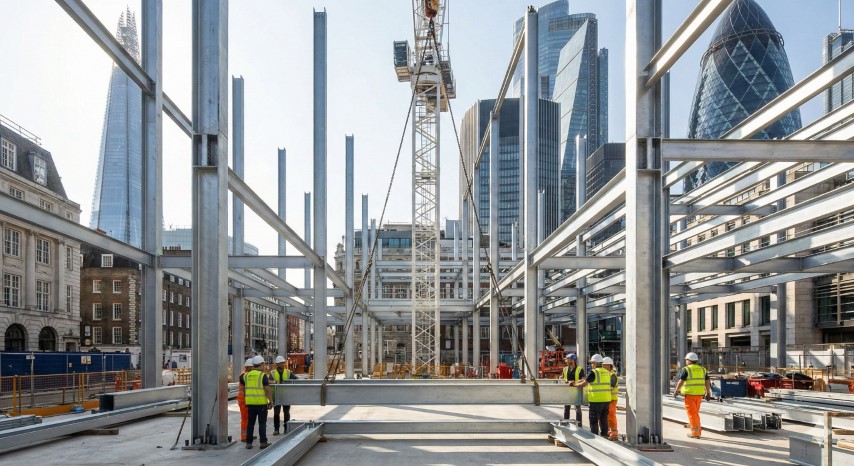

In today’s rapidly evolving construction industry, efficiency, durability, and sustainability are at the heart of every successful project. One of the leading innovations driving this change is the steel frame system—a solution that is quickly becoming the preferred choice for developers, architects, and contractors across residential, commercial, and industrial sectors.

As a specialist subcontractor focused on delivering steel frame-only structures, we’ve seen firsthand how this system can transform the construction process. Here’s why steel frame systems are reshaping the industry:

1. Speed of Construction

Time is money in construction. Steel frame systems are manufactured off-site and delivered ready for installation, significantly reducing build time. This modular approach allows for quicker assembly compared to traditional brick-and-block or timber builds, minimising labour costs and project delays.

2. Precision and Quality Control

Steel components are fabricated to exact specifications in controlled factory environments. This results in consistent quality, fewer errors on-site, and seamless coordination with other trades—especially beneficial for projects where tight tolerances are required.

3. Design Flexibility

Steel’s high strength-to-weight ratio allows for larger spans and more open spaces without the need for load-bearing walls. This opens up countless possibilities in architectural design and interior layout—perfect for modern buildings that value both aesthetics and function.

4. Durability and Longevity

Steel is resistant to many of the issues that commonly affect traditional building materials: it doesn’t rot, warp, crack, or attract pests. With proper coatings, steel structures are also highly resistant to corrosion, ensuring long-term structural integrity with minimal maintenance.

5. Sustainability and Environmental Benefits

Steel is one of the most recyclable materials on Earth. Many steel frame systems are made from recycled content and can be recycled again at the end of their life cycle. Additionally, the precision of off-site fabrication results in less material waste, reducing the environmental impact of each build.

6. Safety on Site

Steel frame construction is generally cleaner and more predictable, creating a safer working environment. The speed and simplicity of on-site assembly reduce the risk of accidents, especially when working with experienced labor-only subcontractors like ours.

7. Adaptability for Future Modifications

Because steel frames are bolted together rather than cemented in place, future expansions or modifications are easier to implement. This makes steel an excellent choice for buildings that may require future reconfiguration—such as schools, healthcare facilities, or commercial units.

Why Work with a Steel Frame Specialist?

At our core, we operate as a one-stop shop for steel frame-only structures, partnering with design firms, manufacturers, and skilled labor teams to ensure a seamless process from design to installation. By focusing solely on steel frames, we bring expert knowledge, efficient project management, and a reliable supply chain to every job.

Whether you’re developing housing schemes, commercial units, or bespoke builds, steel framing provides the strength and flexibility modern construction demands.

Thinking about using a steel frame system for your next project?

We’d be happy to discuss how we can support you—from design collaboration to on-site installation.